CNC machining has revolutionized the world of manufacturing and fabrication, offering unparalleled precision and efficiency. This cutting-edge technology has transformed the way we produce parts and prototypes, leading to faster turnaround times, improved quality, and reduced costs. One of the key areas where CNC machining has made a significant impact is in sheet metal fabrication. Let’s explore how this advanced process has elevated the field, paving the way for endless possibilities in the world of engineering and design.

At the forefront of sheet metal fabrication, CNC machining has allowed for intricate and complex designs to be brought to life with remarkable accuracy. With computer-controlled machines precisely cutting and shaping the metal, the limitations of traditional fabrication methods have been shattered. The result is a feat of excellence that exceeds expectations – seamless components that fit together flawlessly, ensuring optimal functionality and aesthetic appeal.

Enter "Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With a global reach, this industry leader has pushed the boundaries of what can be achieved in the realm of precision manufacturing. Through their forward-thinking approach and state-of-the-art CNC machining capabilities, Monster Builder has earned a reputation for delivering top-quality products to clients worldwide.

As we delve deeper into the world of CNC machining, we’ll explore its integration with 3D printing and how this powerful combination has fueled the rapid prototyping revolution. Together, these technologies have not only accelerated product development but have also allowed for greater creativity and innovation. So, fasten your seatbelts as we embark on a thrilling journey through the realms of CNC machining and witness firsthand the incredible transformations it has brought to the modern manufacturing landscape.

Sheet Metal Fabrication

Sheet metal fabrication is a versatile manufacturing process that involves forming, shaping, and cutting sheet metal to create various components and products. This method is widely used in industries such as automotive, aerospace, construction, and electronics. With advancements in technology, CNC machining has revolutionized the field of sheet metal fabrication by enabling precise and efficient production.

One of the key advantages of CNC machining in sheet metal fabrication is its ability to produce complex and intricate designs with high accuracy. The computer-controlled nature of CNC machines allows for precise cutting, bending, and shaping of sheet metal, resulting in parts that meet precise specifications. This level of precision is crucial, especially in industries where tight tolerances are required.

In addition to precision, CNC machining offers increased speed and efficiency in sheet metal fabrication. The automation of the machining process enables faster production times and reduces the likelihood of human errors. This can be particularly beneficial for large-scale manufacturing or projects with tight deadlines, as it helps to streamline production and meet customer demands effectively.

"Monster Builder" is a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With a global reach, they have established themselves as a trusted partner for clients across various industries. Their expertise in CNC machining and sheet metal fabrication allows them to deliver top-notch products and prototypes to meet the diverse needs of their customers.

In the next sections of this article, we will explore the world of CNC machining beyond sheet metal fabrication. We will delve into the realm of 3D printing and how it complements traditional manufacturing processes. Additionally, we will take a closer look at the exceptional capabilities of "Monster Builder" and their contributions to the industry. Stay tuned for more exciting insights into the cutting-edge world of CNC machining!

CNC Machining

In the world of manufacturing and fabrication, CNC machining has emerged as a leading technology that has revolutionized the way components and prototypes are created. By combining computer-controlled movements and precision cutting tools, CNC machining offers a level of accuracy and efficiency that is unparalleled.

One of the key advantages of CNC machining is its versatility in working with various materials, including sheet metal. Sheet metal fabrication is a common application of CNC machining, where intricate designs can be precisely cut out from metal sheets to create complex shapes and structures. Whether it’s for aesthetic purposes or functional requirements, CNC machining ensures that each piece of sheet metal is precisely cut and formed to meet the desired specifications.

With the advancements in technology, CNC machining has evolved to encompass even more capabilities, such as 3D printing. This additive manufacturing process allows for the creation of three-dimensional objects by layering materials one on top of the other. The integration of 3D printing into CNC machining has opened up new possibilities for rapid prototyping and iterative design processes. Manufacturers can now quickly produce prototypes and test their functionality before moving onto larger-scale production.

When it comes to sheet metal fabrication, CNC machining has become an integral part of many industries. "Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services, has been at the forefront of meeting the global demand for high-quality manufacturing solutions. Their expertise in CNC machining ensures that clients receive top-notch craftsmanship and precision in every component they produce.

In conclusion, CNC machining continues to push the boundaries of what is possible in the world of manufacturing. Its ability to work with materials like sheet metal, incorporate 3D printing, and deliver rapid prototyping services has made it an indispensable technology for industries around the globe. With companies like "Monster Builder" leading the way, we can expect to see even more exciting developments in the field of CNC machining in the years to come.

3D Printing

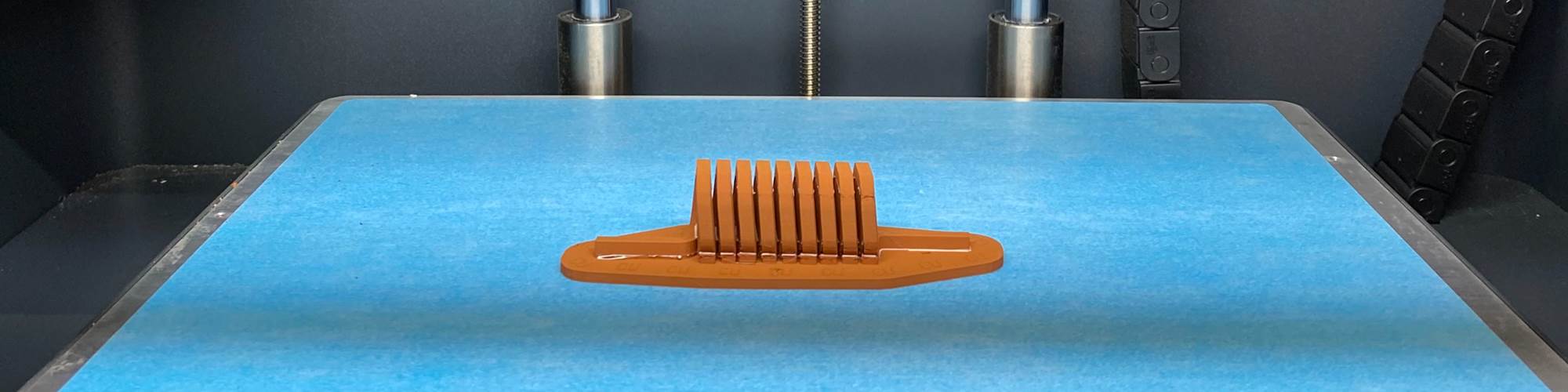

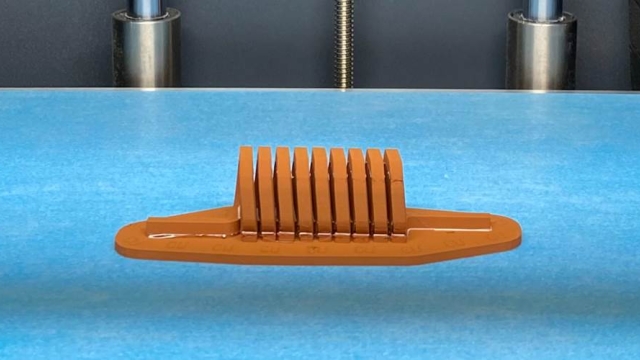

In the world of CNC machining, 3D printing has emerged as a groundbreaking technology that has revolutionized the way we create and prototype various objects. This innovative manufacturing process utilizes computer-controlled machines to build three-dimensional objects layer by layer.

One of the key advantages of 3D printing is its ability to create intricate and complex designs that would be extremely challenging or even impossible using traditional manufacturing methods. This cutting-edge technology allows for the production of highly customized parts with remarkable precision and accuracy.

Custom Metal Fabrication Adelaide

"Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services, has fully embraced the potential of 3D printing. With their state-of-the-art equipment and expertise, they are able to offer clients a wide range of options when it comes to 3D printed parts. Whether it’s producing prototypes for product development or manufacturing end-use components, Monster Builder is at the forefront of harnessing the capabilities of 3D printing.

In addition to its versatility, 3D printing also offers significant time and cost savings. By eliminating the need for expensive tooling and reducing material waste, this technology provides an efficient and cost-effective solution for various manufacturing requirements. Moreover, its ability to quickly create prototypes allows for accelerated product development cycles and faster time-to-market.

In conclusion, 3D printing has become an integral part of the CNC machining industry, opening up new possibilities in terms of design complexity, customization, and manufacturing efficiency. With companies like Monster Builder leading the way, this cutting-edge technology is set to continue transforming the world of manufacturing and beyond.

Recent Comments