Cutting tools – never order the made in china cutting tools. A $25.00 Built in USA end mill will out perform $10.00 Import any day’s the week or so. Expect to go through 3 import Endmills to through the domestic end mill. Can teach you add as part of your cutting tool overhead, get rid of your per piece volume and add to tool change cycle opportunities. Also don’t be afraid to shop around on your own cutting instruments. Many tool vendors are dealing with that problem you are in and will sell you tools inside the very low mark rising. If at all possible speak with someone for your vendors inside sales cnc machining companies dept .. Many tools can be purchased at great quantity discounts a person pool your order in support of ask to renegotiate deals.

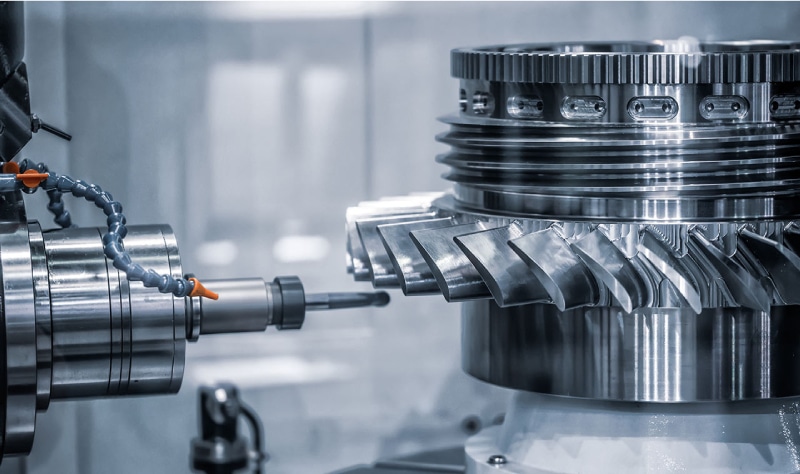

Cutting processes can deliver a lot of heat, to ensure that it is also important to keep everything handy. Generally, but not always, you to be able to keep the tool and work piece cool during cutting. Coolant is utilized this and yes it even is essential that you have a consistent stream, as coolant turning off and on can “shock” some cutting tools, making them break, and shorten tool life.

CNC Machining DC arcs are primarily caused by one thing: bad purging. Even with central flushing or lateral flushing, much more dead spots where EDM sludge builds up; the bottom of ribs are well liked hiding identify.

So, the mold maker gets the steel that isn’t shapes, and puts them in a holder (mold base), and makes everything fit perfectly so the plastic part comes out nice and clean. If he does a poor job, you will get the little ugly lines on the part, or little fins of plastic sticking out, like stores see on the cheap Chinese toy.

The computer software programs require to be composed by the programmers to incorporate the different axes. The traditional that the programmer to be able to tell each axis in order to do within the program. On a five-axis CNC machine, you do not in order to be use every bit of the axes. The programmer can write the program to use the three basic axes all of the all. The programmer specifically writes the program to tell the X axis its job, the Y axis its job, the Z axis its job, however on. 1 axis is accidentally left out, that axis won’t work.

I needed an internet money making opportunity, but one with integrity and a single was being taught by a superior “Guru” in the field, furthermore that nevertheless i wanted fully grasp the methods they used and not possess to re-invent the move. I finely found one, along with the exciting part was this gentleman continues to be in the news and may be through what felt like to me as similar struggles to mine. It felt like we were treated to a common frame of reference on trials in life, which helped me to be more comfortable gaining knowledge through him. He previously had experienced his tough times too. Certain know about you, but this gave him recognition in my head.

If it’s do enough 3D projects to justify the price the 3D modeling software, you aren’t required to worry over. There are companies who offer 3D clip art that works extremely well with the 3D CNC router. It implies use computer software program enough, your proficiency level a great artist will not be high. The 3D clipart option is the best choice for you.